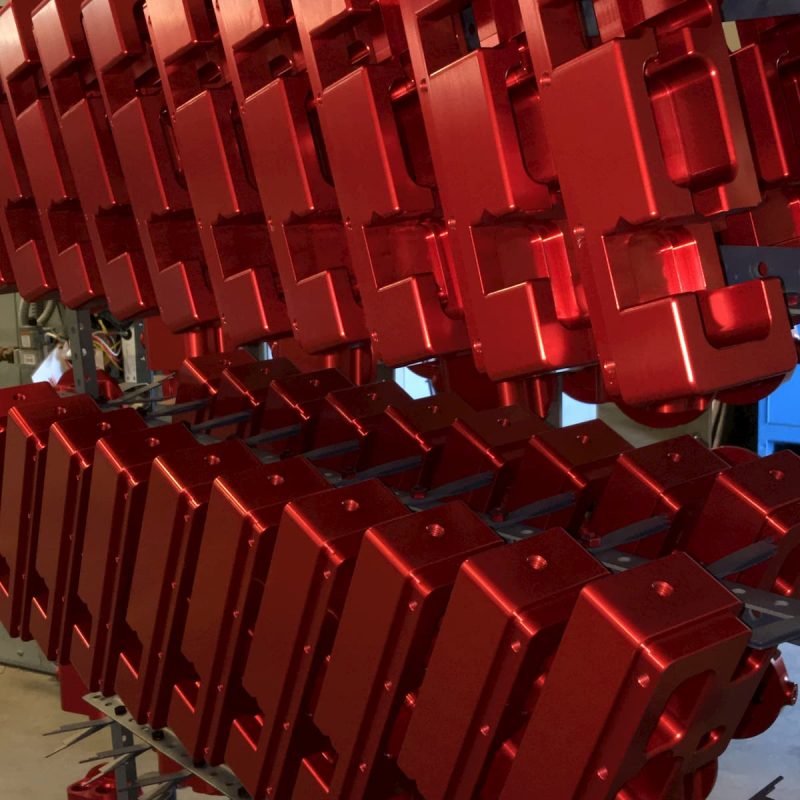

Anodizing

Anodizing is an electrochemical process done by placing aluminum parts in a sulfuric bath. This builds aluminum oxide on the surface and the material of the part as well. Typical coatings range in thickness between .00007” to .001”. Type II Anodize comes in clear as well as a variety of colors and adheres to the standard military spec Mil-A-8625.

If you are looking for a color not specified on the list of dyes, please contact us for availability of providing a custom dye.

Locations providing Anodizing

Anodizing details

Note: tank sizes and max part sizes listed only apply to our Portland facility. Please call (775) 355-8121 for tank size details at our Sparks facility.| Process | Max Tank Size | Max Part Size |

|---|---|---|

| Type II Anodize | 120” x 72” x 60” | 110” x 22” x 54” |

| Type III Hard Anodize | 120” x 72” x 60” | 110” x 22” x 54” |

| Type Ic Boric Anodize | 84” x 36” x 60” | 80” x 32” x 54” |

| Black Dye | 120” x 72” x 60” | 110” x 22” x 54” |

| Gold Dye | 120” x 18” x 60” | 110” x 12” x 54” |

| Specification Type | Specification |

|---|---|

| MIL SPECS | Mil-A-8625 Type 1C |

| Mil-A-8625 Type 1C | |

| Mil-A-8625 Type IIB | |

| Mil-A-8625 Type II, Class 1 | |

| Mil-A-8625 Type II, Class 2 | |

| Mil-A-8625 Type III, Class 1 | |

| Mil-A-8625 Type III, Class 2 | |

| Mil-A-63576 Type I | |

| Mil-STD-171 7.2-7.2.2 | |

| Mil-STD-171 7.5-7.5.2 |