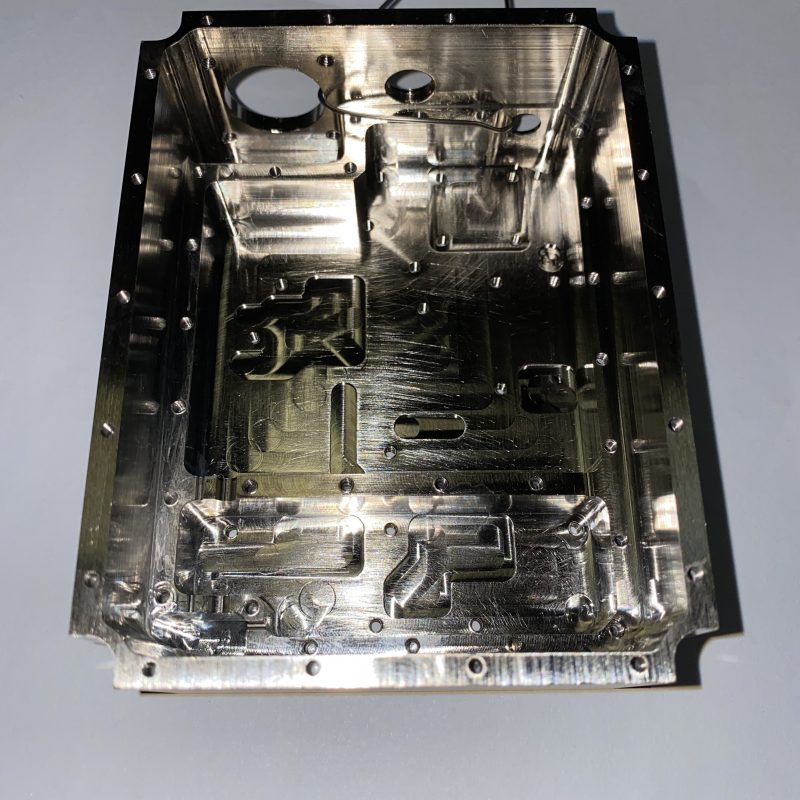

Electroless Nickel

Electroless Nickel plating does not use electric current to produce a deposit, but rather operates chemically. The Electroless process (autocatalytic deposition), deposits a uniform coating regardless of the shape or surface of the part, thus overcoming the difficulty of uniformly plating irregularly shaped parts or components. Electroless Nickel has gained popularity due to its ability to provide uniform coverage with excellent hardness and high lubricity.

Locations providing Electroless Nickel

-

Portland

Apex Anodizing (HQ)

7015 NE Columbia Blvd.

Portland, OR 97218

Electroless Nickel details

Note: tank sizes and max part sizes listed only apply to our Portland facility. Please call (775) 355-8121 for tank size details at our Sparks facility.| Process | Max Tank Size | Max Part Size |

|---|---|---|

| Electroless Nickel | 72” x 42” x 60” | 68” x 36” x 52” |

| Specification Type | Specification |

|---|---|

| AMS 2404 Rev G | Class 1 |

| Class 1 | |

| Class 2 | |

| Class 3 | |

| Class 4 | |

| ASTM B733 | Type I |

| Type I | |

| Type III | |

| Type IV | |

| SC1 | |

| SC2 | |

| SC3 | |

| SC4 | |

| Class 1 | |

| Class 2 | |

| Class 3 | |

| Class 4 | |

| Class 5 | |

| Mil-C-26074 | Class 1 |

| Class 1 | |

| Class 2 | |

| Class 3 | |

| Class 4 | |

| Grade A | |

| Grade B | |

| Grade C |